In an era defined by climate change and surging energy demands, the unglamorous refrigeration system has unexpectedly become a high-stakes arena for technological innovation.

From the vast racks cooling supermarket aisles to the ultra-low temperature units preserving vaccines, refrigeration accounts for an estimated 15% of the world’s total electricity consumption. Now, a powerful twin mandate is driving the industry’s transformation: slashing this enormous energy draw and eliminating the use of traditional refrigerants with high Global Warming Potential (GWP).

The End of HFCs and the Rise of Naturals

The most immediate catalyst for change is the global phase-out of hydrofluorocarbons (HFCs), potent greenhouse gases thousands of times more damaging than CO2. International agreements, such as the Kigali Amendment to the Montreal Protocol, are compelling a rapid shift toward natural refrigerants.

These eco-friendly alternatives—including carbon dioxide (CO2), ammonia (NH3), and hydrocarbons like propane (R-290)—have zero or near-zero GWP, making them future-proof from a regulatory standpoint. For instance, propane (R-290) has a GWP of just 3, compared to over 1,400 for a common synthetic HFC like R-134a.

- Carbon Dioxide (CO2) Systems: Known as transcritical systems, these are gaining significant traction in commercial refrigeration, offering efficient cooling despite operating at very high pressures. Recent advancements, like the use of ejectors, are even enabling CO2 to be efficient in hotter climates.

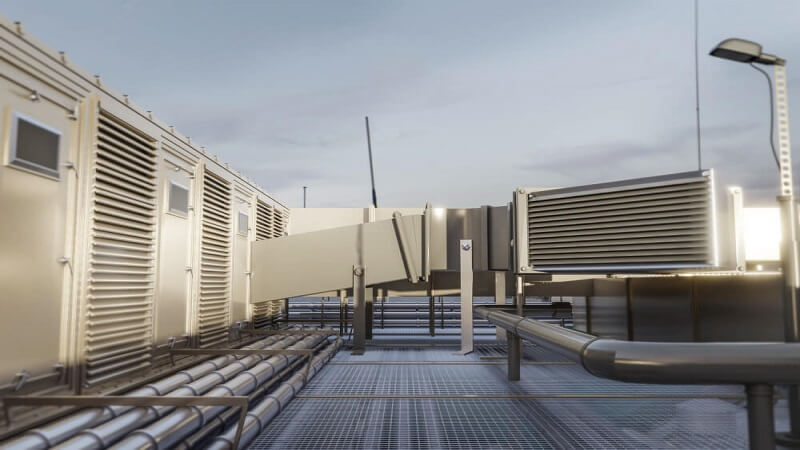

- Ammonia (NH3): While toxic and requiring strict safety protocols, ammonia remains the most efficient and cost-effective solution for large-scale industrial refrigeration and cold storage warehouses.

- Hydrocarbons (R-290, R-600a): These are common in smaller commercial appliances like display cases and freezers, offering high efficiency at a low environmental cost.

Digitalization: The Quest for Peak Efficiency

Beyond the refrigerant itself, manufacturers are focused on maximizing the Coefficient of Performance (COP)—the measure of a system’s energy efficiency. This is being achieved through sophisticated digitalization and advanced component design.

- Variable Speed Compressors: Like a modern car engine, Variable Capacitive Compressors (VCCs) and Variable Speed Drives (VSDs) modulate their output to match real-time cooling demand. Unlike old fixed-speed compressors that simply cycle on and off, VCCs operate continuously at varying speeds, reducing on/off cycling, improving temperature stability, and dramatically cutting energy consumption—sometimes by over 50% in commercial settings.

- IoT and AI Integration: Modern refrigeration systems are no longer isolated units. They are equipped with IoT sensors that monitor temperature, pressure, and energy use in real-time. This data feeds into Energy Management Systems (EMS) that use AI to predict demand, optimize defrost cycles, and adjust set-points dynamically, leading to energy savings of up to 15% in complex cold storage facilities.

- Waste Heat Recovery: A major trend is the integration of heat recovery systems. Since refrigeration systems generate enormous amounts of waste heat, this heat is now being captured and redirected to warm a building’s interior space or heat water, effectively maximizing total system efficiency and providing a double benefit.

The future of refrigeration is clean, smart, and efficient. As global cold chain logistics rapidly expand to meet demand for fresh food and pharmaceuticals, these technological advancements are not just critical for corporate bottom lines, but are essential tools in the urgent global mission to mitigate climate change.